Storage racks are shelf-like frameworks or stands found in plants and factories, workshops, retail facilities, homes, and offices alike. The applications of storage racks are virtually endless. They offer their users a means to efficiently store, organize, and/or display tools, equipment, materials, pallets, boxes, parts, and products. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Quality Material Handling (QMH) is a leading total solutions provider for boltless shelving, warehouse racking, storage systems, mezzanines, and dock equipment. With over 29 years of experience and an in-house fabrication facility, QMH designs and manufactures innovative custom solutions such as dock platforms and ramps that solve difficult loading and unloading challenges. We are a full-service...

Established in 1972, RACK USA provides storage solutions for material handling applications. We design heavy load racks, medium load racks, retail fixtures, and custom industrial rack solutions. Hundreds of clients can attest to our expertise and dedication to quality.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

At North American Steel, our focus is on delivering top-tier storage solutions that optimize space and efficiency across industries. Specializing in the design, manufacturing, and installation of storage racks and steel shelves, we provide a comprehensive range of high-quality rack systems that cater to diverse storage needs.

Advance Storage Products produces structural and pushback rack systems. We emphasize unsurpassed quality, reliability and on-time delivery. Through outstanding execution, implementation and design we offer best in class industry solutions that make the most of our customers’ space. Our team approach insures your project receives the best engineering, project management and customer service to...

More Storage Rack Manufacturers

Storage racks also provide invaluable space saving services inside shipping areas, product assembly rooms, workspaces, and manufacturing facilities.

Examples of the industries for which storage racks may hold inventory include home furnishings, garage and automotive services, food and beverage, education, material handling, postal services, healthcare, banking, military, government, office, industrial manufacturing, and more.

History

Storage racks are a variation on the basic shelving unit. Shelving units, of course, have been around in some form or another for a very long time. So, what prompted the evolution of the storage rack, and when did it happen? It was a combination of industrialization and the invention of the forklift. First, during the early 1900s, manufacturers required an amping up of storage. This was because they were creating more and more bulk items and items for large stores, and they were manufacturing more products because they had the means to ship them across the country. In response they began creating larger storage systems. Then, in 1917, after putting in years of work, an American company called the Clark Material Handling Company came out with the first forklift. The invention of the forklift allowed manufacturers to create taller and more expansive storage racks. It also allowed them to move things more quickly and more safely, with less people.

During both World Wars I and II, manufacturers saw an increase in their need for storage racks that coincided with the demand for vehicles, weapons, and goods for the war effort. Around this time, engineers developed the standardized pallet. This also led to the creation of forklifts that could lift several pallets at once. In response to this new capability, engineers created the pallet rack. Pallet racks, the first true storage rack, simply hold these pallets. In 1926, manufacturers installed the first vertical pallet storage racks. Used in warehouses, they allowed workers to make better use of space by stacking products upright.

In 1968, an American inventor named Thomas J. Finlayson patented his design for a drive-in pallet rack. This type of storage rack permits machinery operators to drive directly to the storage rack. Almost twenty years later, in 1986, another American inventor, Charles “Chuck” Agnoff designed the gravity flow storage method, which to this day helps manufacturers more effectively and efficiently use their storage rack systems. Today, storage racks are more useful than ever, as well as more durable, secure, and versatile.

Design

Storage rack manufacturers build their products using welding. Welding ensures that the materials are strong and will stay together. Usually, the parts they weld together are made from a strong metal, like stainless steel, aluminum, or even titanium. When a customer requires less durability, manufacturers may also use something like particle board or wood. Manufacturers choose materials based on customer specifications, like required durability, required temperature resistance, required corrosion resistance, etc.

Manufacturers can fabricate or assemble storage racks based on a variety of designs. To get started, customers may interact with their suppliers in a number of ways. First, they may choose from stock dimensions and designs. Second, they may present a detailed custom request. Third, they may work with their storage rack provider to come up with a custom design.

In the case of the lattermost, manufacturers and customers discuss a variety of application details, including specifications and requirements, available floor and ceiling capacity, how much storage space is adequate, what load bearing capacity they need, and what type of mobility, if any, they require. After these discussions, the rack manufacturer will sketch a system design and submit it for approval to their customer. Once cleared, they can begin fabrication. For standard or custom ordering, reach out to a reputable storage rack manufacturer today.

Features

All storage rack systems are operated using either a “first in, first out” (FIFO) organization method or a “last in, first out” (LIFO) organization method. Each method informs workers differently as to how to stock and pick material.

The first method, FIFO, calls for stocking to be done in the rear and picking to be done at the front. Quite commonly, this technique is used with perishable food inventory, which must hold to this order so that the oldest items get moved out first.

The LIFO technique is never used with perishable items. Rather, it is used with products that can sit at the back of storage shelves for long periods of time without detriment. Mostly, LIFO is used with push-back racks and other storage racks that benefit from its space-saving attributes.

Types

Some of the most common storage rack design types include industrial storage racks, metal storage racks, wire storage racks, pallet racks, flow racks, push-back racks, rolling racks, and cantilever racks. In addition, less common, but still an important storage rack type are cryogenic racks.

Industrial storage racks are heavy duty storage racks made to hold heavy items and machinery. They are always made of a durable metal like stainless steel.

Metal storage racks are any and all storage racks that are made of metal. Most often, this metal is steel or aluminum. Such racks are used for heavy duty warehouse storage applications. (When used in a warehouse, metal storage shelving units may be called storage racks.) Manufacturers seeking lightweight storage can purchase racks made of particle board, wood, or titanium.

Wire racks are storage racks composed of vertical metal rails, with woven wire mesh decks or welded wire mesh decks. They may also feature open shelves. Their grid patterns make them ideal for display applications. The patterns also increase ventilation and decrease dust buildup.

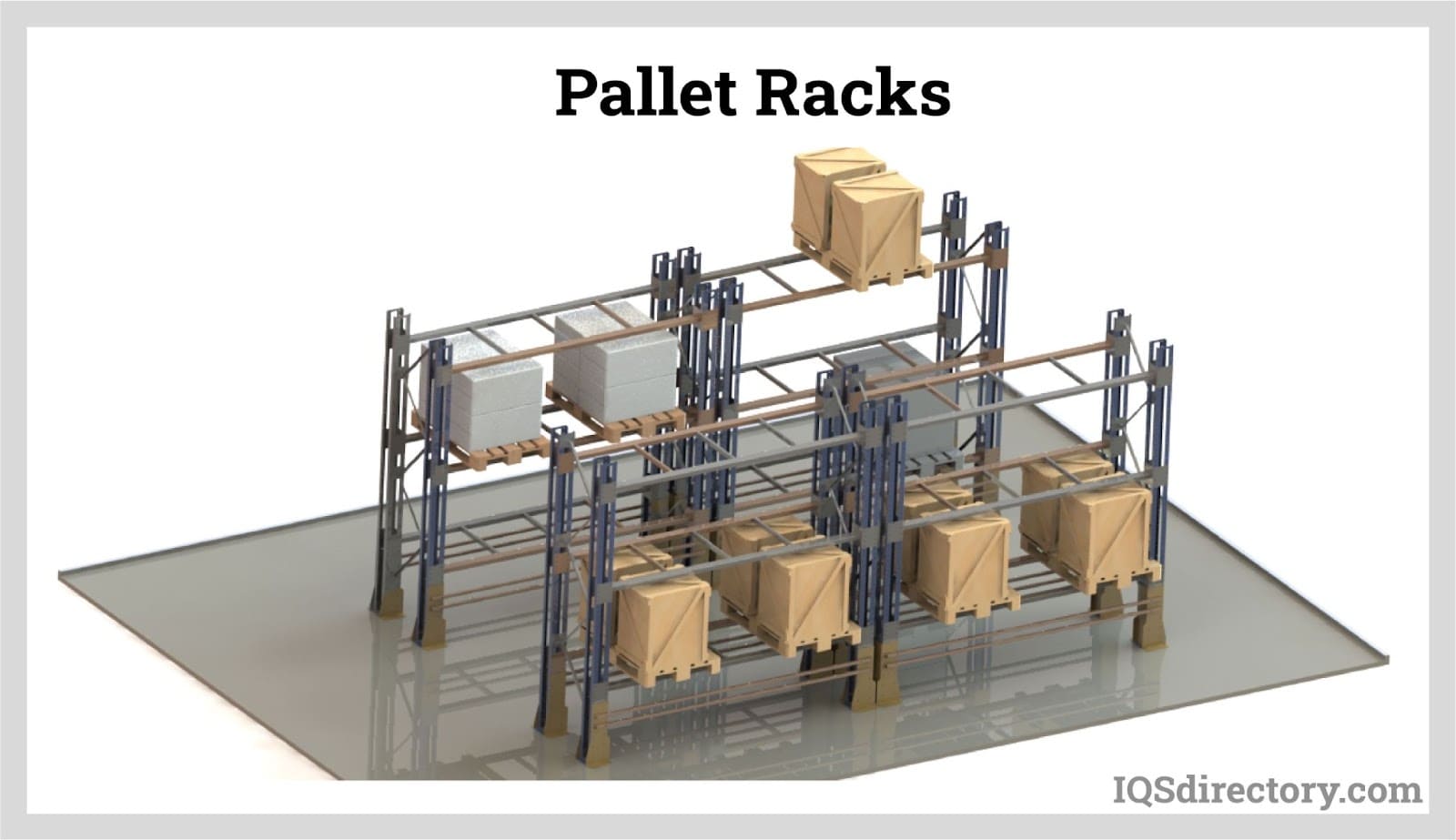

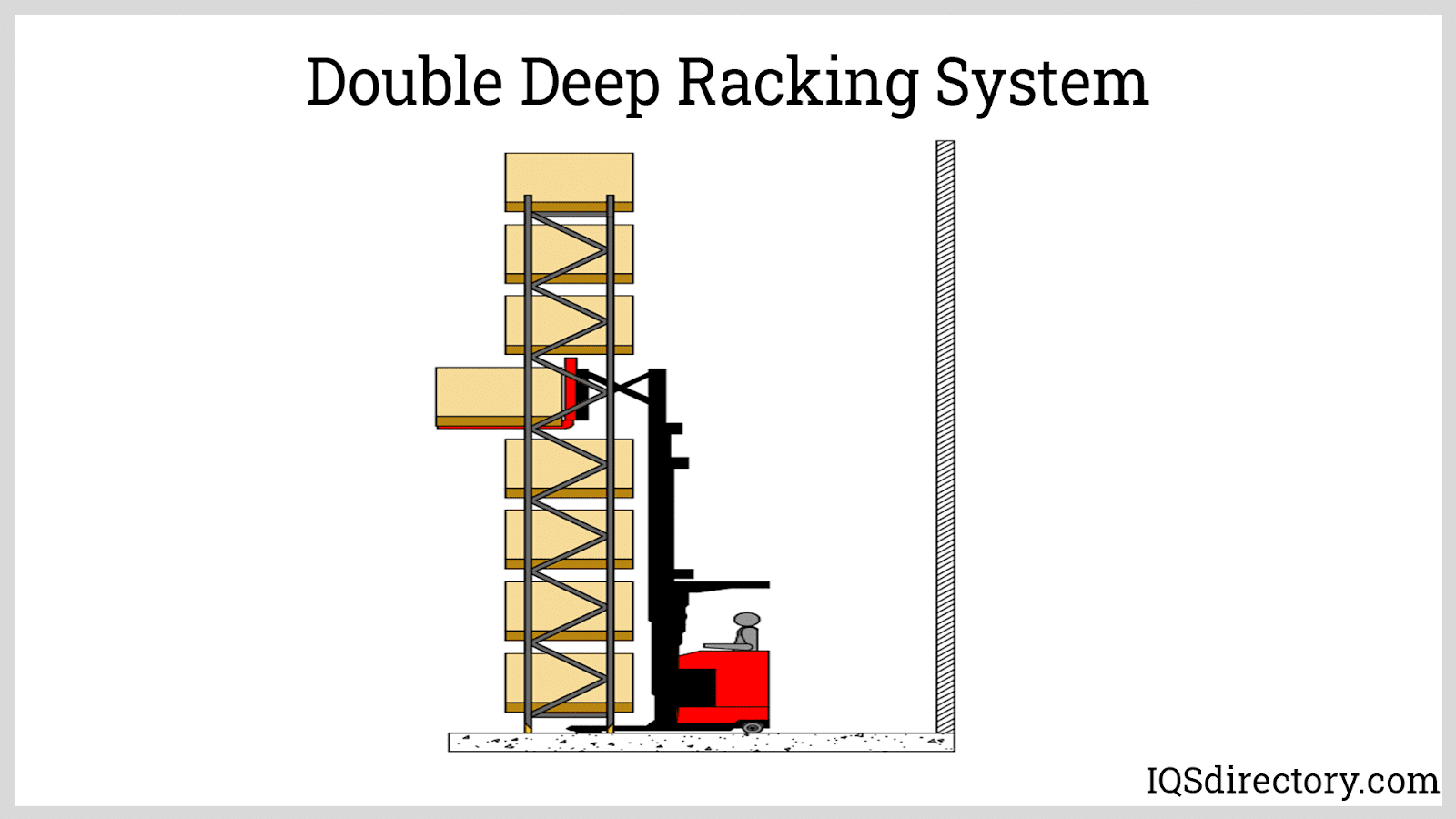

Pallet racks are designed to store inventory on pallets, or skids. Pallet racks are open on all sides and allow for vertical stacking. They have been popular since World War II and have applications in warehouses, retail centers, manufacturing facilities, and distribution centers. As such, pallet racks, which are usually moved by forklifts, are available in a variety of configurations. Pallet rack subtypes include drive-in racks, drive-through racks, pallet flow systems, push-back pallet rack systems, and compact mobilized pallet racks.

Flow racks, also called gravity flow racks, simply move pallets along the sloped plane of their decking when they are placed on top of their rollers. Flow racks and push-back racks alike offer safe, dynamic, high-density storage for cartons and pallets. Using inclined decking made up of rails and rollers, they both use depth and gravity to increase rack capacity.

Push-back racks store each pallet on a wheeled cart that is placed on the system’s rails. Angled slightly down, when a forklift places pallets on them, the carts move quickly towards the load/unload area and bumps the row of carts backwards. By staying close together, push-back racks save significantly on space. Push-back racks are open on one side and can easily be stored against an obstruction like a wall.

Rolling racks may be static, used in picking and storing systems, or portable, like a wire storage rack, and able to be shifted from one location to another within a warehouse.

Cantilever racks consist of a vertical column, arms, a base, and cross and/or horizontal brace sets. Modular, they are capable of accommodating new or changing storage requirements by allowing additional elements to be added to themselves. Used in plumbing supply warehouses, lumber yards and woodworking shops, cantilever racks are made to hold long, heavy items, especially those that must be kept up off the ground, such as sheet metal, beams, boards, and rails.

Cryogenic storage racks are storage racks used for the storage of materials at extremely low temperatures. Cryogenics is a branch of physics that works with materials at temperatures below 292℉ (temperature cutoff point designated by the U.S. National Institute of Standards and Technology).

Around the house, homeowners use storage racks not only to organize the garage or basement, but for a number of specialty tasks as well. Storage racks created for specialty storage solutions like these include amp racks, bicycle racks, eco racks, and drying racks.

Amp racks are storage racks upon which amplifiers and other professional audio equipment are mounted.

Bicycle racks are storage racks where bikes are stored when not in use.

Eco racks are a type of bike rack designed to make it possible for bike riders to haul a similar amount of weight that they could using a car. They call them eco racks because commuting with bikes is both eco-friendly and economical.

Drying racks are storage racks for hanging up wet clothes.

Accessories

There are several accessories available for storage racks that can enhance their functionality and adaptability. Casters or wheels, for instance, are often used to add mobility to racks, allowing them to be easily moved or repositioned. Braces, meanwhile, are used to provide additional stability and strength to the rack, especially when heavy or bulky items are stored. Additionally, anchors are used to secure the rack to the floor or wall, preventing tipping or accidental displacement. Finally, bumpers are protective elements attached to the rack to prevent damage from collisions or impacts.

Drawer rack add-ons are designed to convert open shelving into drawers, providing enclosed storage for smaller items. Shelf units, for example, are additional shelves that can be added to expand the storage capacity vertically. Baskets, meanwhile, offer a convenient solution for storing loose or irregularly shaped items, keeping them organized and easily accessible. Feet, on the other hand, are used to elevate the rack off the ground, protecting the contents from moisture or facilitating cleaning underneath. Dividers are useful for creating separate compartments within a shelf or drawer, enabling better organization and segregation of items. Lastly, arms or hangers can be attached to the sides of the rack to hang tools, clothing, or other items, maximizing storage space.

To determine which storage rack accessories are needed for a specific application, several factors should be considered. First, assess the intended use of the rack and the type of items to be stored. For example, if mobility is required, casters or wheels would be beneficial. If the rack is tall or will hold heavy items, meanwhile, braces and anchors may be necessary to ensure stability and safety. Additionally, consider the available space and layout to determine if additional shelves, baskets, or dividers are needed for optimal organization. Assess any specific requirements such as protecting delicate items with bumpers or utilizing hanging storage with arms. By evaluating the specific needs of the application, you can select the appropriate accessories to enhance the functionality and efficiency of your storage rack.

Standards

Because storage racks are so often used in the workplace, in the United States, they must always meet OSHA safety requirements. Other storage rack standard requirements vary based on your application and location. For instance, if your storage racks are located in a public area prone to seismic activity, like a public library, they must meet the design and installation standards of FEMA. Any storage racks to be used in the medical industry or food and beverage industry must be assigned FDA standards. The same goes for storage racks used in other settings, like military bases (Mil-Specs), the office, accessible areas (must be ADA-compliant), and so. Some of the organizations that most frequently issue standard guidelines include ANSI (American National Standards Institute), ISO (International Organization for Standardization), and the NFPA (National Fire Protection Association).

Things to Consider

Find the right storage rack manufacturer for you by checking out those we have listed on this page. All of those we list are reputable and proven leaders. To help you focus your search, we recommend you compile a list of your own. This should include all of your specifications, including things like your budget, your timeline, your delivery preferences, and your post-delivery support preferences (installation assistance, maintenance support, warranties, etc.).

With your list in tow, take some time to browse the respective profiles of the companies we have posted on this page. Compare and contrast their services and product offerings. Pick out three or four you believe to be the best potential fits for you, and then reach out to each of them. Once again guided by your specifications list, discuss your application at length with your candidates. Finally, choose your manufacturer. Remember to base your decision not only on which one offers you the best prices, but also which one provides the storage solution that most closely aligns with your needs. Good luck!

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services