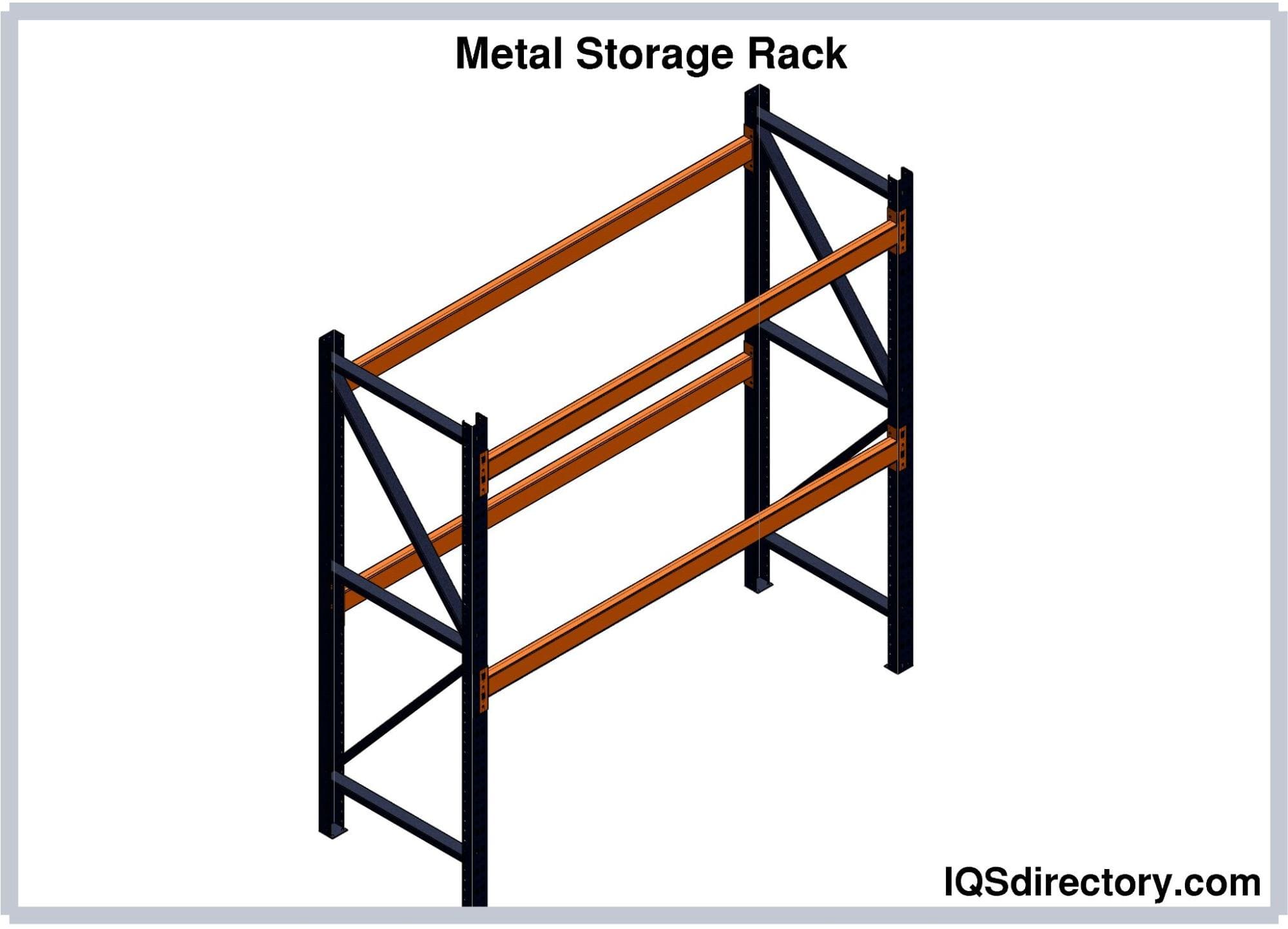

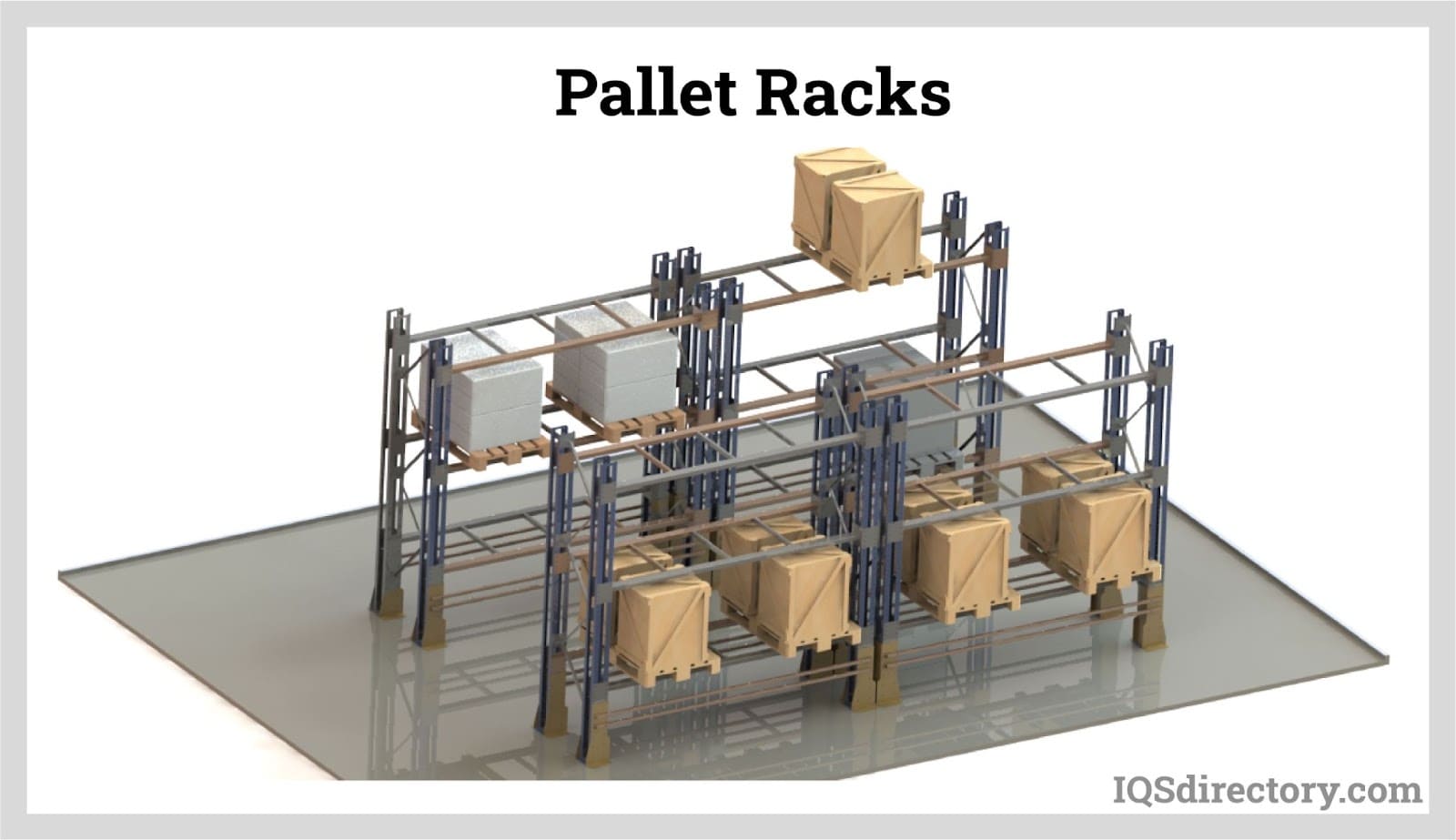

Metal storage racks’ main parts are either bolted or welded together, and they have incredibly long lives, even under constant stress. As a result, metal storage racks are widespread in industrial settings due to their strength, durability, and capacity to handle many pounds per square inch (psi). In contrast, wire storage racks are frequently used in homes and offices. They have requirements for width, height, depth, material utilized, surface polish, and a maximum of five levels. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Quality Material Handling (QMH) is a leading total solutions provider for boltless shelving, warehouse racking, storage systems, mezzanines, and dock equipment. With over 29 years of experience and an in-house fabrication facility, QMH designs and manufactures innovative custom solutions such as dock platforms and ramps that solve difficult loading and unloading challenges. We are a full-service...

Established in 1972, RACK USA provides storage solutions for material handling applications. We design heavy load racks, medium load racks, retail fixtures, and custom industrial rack solutions. Hundreds of clients can attest to our expertise and dedication to quality.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

More Metal Storage Rack Manufacturers

While some varieties can be adjusted, others are made to accommodate certain objects, such as pallets, long components, timber posts, or metal rods. Many different industries, including the food and beverage, restaurant, pharmaceutical, tobacco, metal fabrication, grocery, storage, shipping, and electronics industries, among others, use metal storage racks to hold materials, tools, equipment, parts, finished products, boxes, trays, and packaging materials.

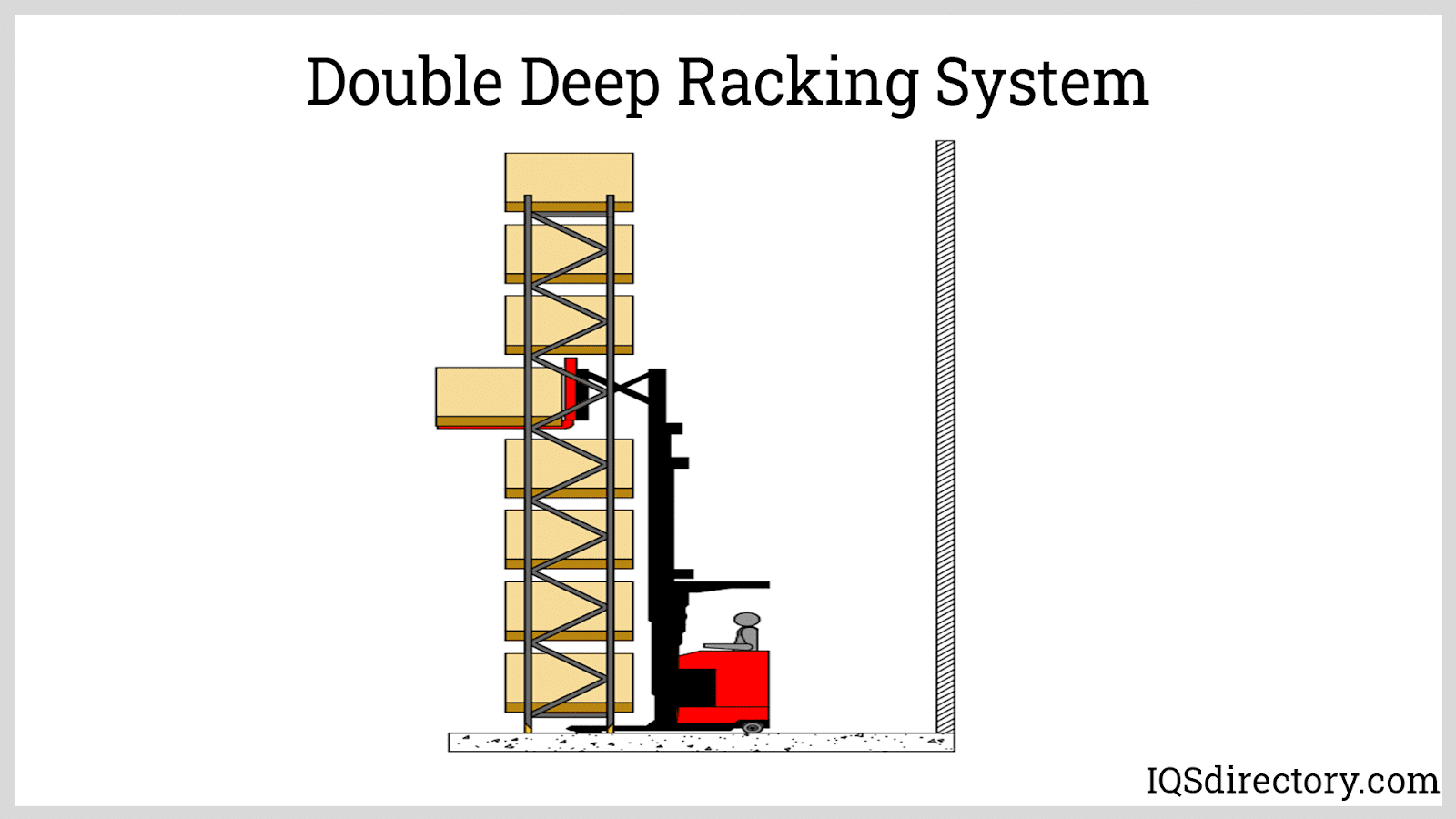

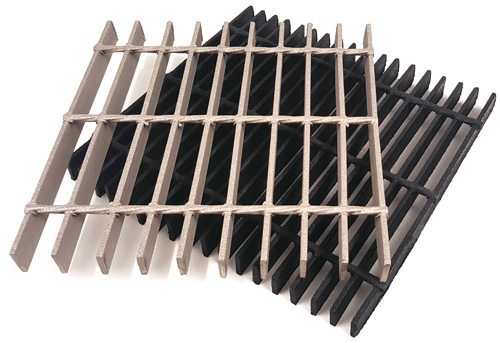

Metal racks come in a wide variety of designs. Some are made using a wire deck woven together or soldered at cross points, making them exceedingly light but sturdy. They are utilized when the stored objects need to have excellent visibility. Additionally, they stop dust from accumulating and are simple to clean by spraying down. The ability to pick using the FIFO (first in, first out) or LIFO (last in, first out) methods is provided by some incline-set storage rack systems.

Materials Used in Making Metal Storage Racks

Metal racks are made from a variety of materials, including:

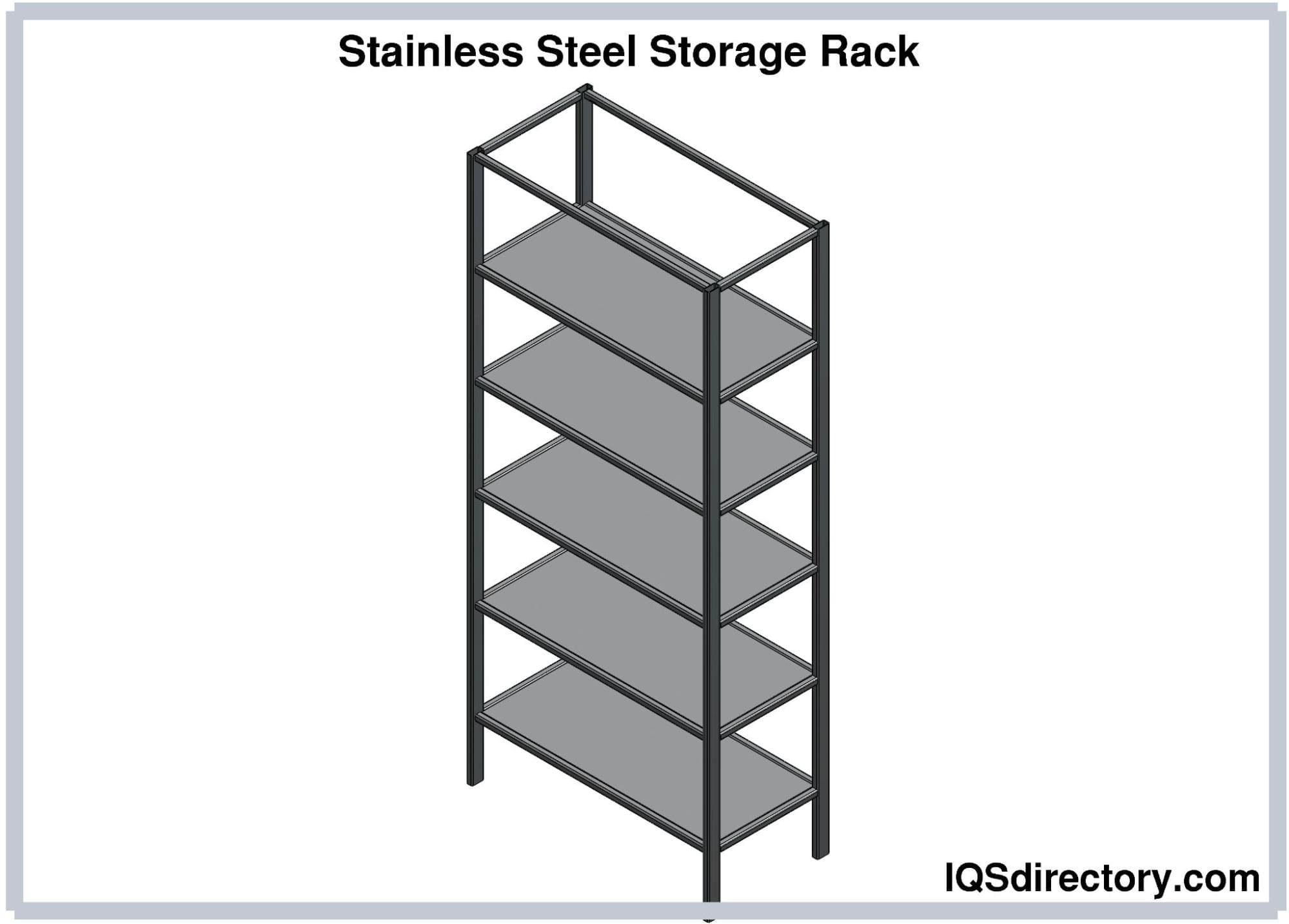

Stainless Steel Storage Racks

One of the most frequently utilized materials for creating metal shelves is steel. This is because steel has strong, adaptable qualities. In addition, due to steel's superior strength over alternative storage rack materials, many firms chose stainless steel for their rack needs. Stainless steel is safe and can handle large loads and high temperatures. The food business is a good example, as they select rack units made of stainless steel since it can sustain large weights of food stock and beverage supply. In addition, steel is simple to clean and less likely to sustain damage. Superior storage rack units can last longer than other types of shelf materials.

Forged Iron Storage Racks

Another metal that works well for metal rack units is forged iron. Because of its adaptability, toughness, and elegant patterns, this type of metal is primarily utilized to make furniture. With all these wonderful qualities, wrought iron is also resistant to water, capable of supporting any load, and less prone to damage. Even though wrought iron is expensive, it is worthwhile to utilize it for storage purposes, such as creating metal storage cabinet units. The advantages of wrought iron include its high quality, dependability, and attractive appearance.

Copper Storage Racks

Copper is a precious metal that is frequently used to create commercial racks. In addition, it is a well-known option for decorating interiors. In addition to being sturdy and having excellent conducting qualities, copper exhibits great resistance to corrosion.

Metal Storage Rack Types

The various styles of metal racks consist of the following:

Steel Racks in the Clip Style

Clip-style steel racks are often adaptable, inexpensive, and long-lasting. Due to these characteristics, it is one of the most widely used styles of metal racks in business and retail environments. With the added convenience of compression clips, clip-style steel racks offer all the benefits of steel while also meeting all demands by making it simple to configure the shelves.

Clip Style, Closed Metal Racking

Steel is the best material for heavy-duty applications since it can support heavy weights and has a long lifespan. However, cartons and other relatively tiny things are stored on steel racks. But as long as it fits within the system's weight capacity and the units are properly arranged, clip-style steel racks can hold practically anything. In addition, steel racks can accommodate products of the majority of shapes and sizes because the shelf heights are completely adjustable.

Bulk Storage Racks

For distribution centers and warehouse owners, bulk storage racks are the best way to handle wide or bulky items. Wide-span racks, also referred to as bulk racks, are typically bolt-free and simple to assemble and adjust.

Riveted Shelves

These shelves are the best racks for individuals who prioritize convenience and toughness. This innovative, adjustable design can support high loads without the use of clips or bolts. Though there are numerous varieties of rivet racks, some can support larger loads than others. Metal wiring or particle board can be used to create the actual shelves on rivet systems. Although particle board is frequently inexpensive, wire is more resistant to moisture and severe temperatures than particle board.

Advantages of Metal Storage Racks

- Made of strong metal material

- Higher shelf weight capacity

- Weight capacity can be adjusted through modifications

- Multi-level storage systems optimize space

- Great accessibility

- Aesthetically beautiful and ideal for use at the front of stores

Choosing the Correct Metal Storage Rack Company

To make sure you have the most positive outcome when purchasing metal storage racks from a metal storage rack company, it is important to compare at least 4 companies using our metal storage rack directory. Each metal storage rack company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each metal storage rack business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple metal storage rack businesses with the same quote.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services