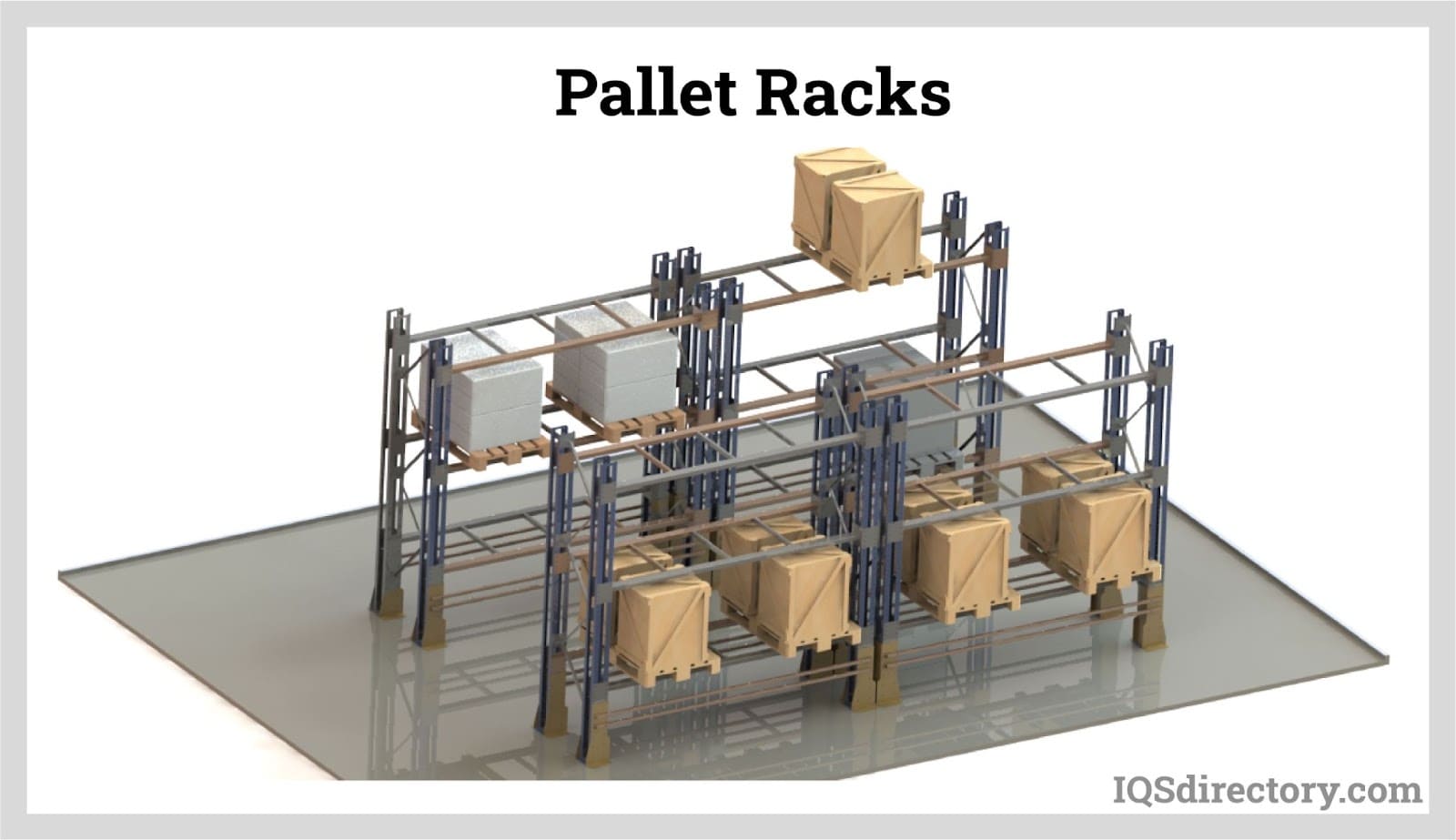

Roller racks are very common in the manufacturing and industrial world. Roller racks are known as flow or push-back types of pallet racks. Where pallet racks are the simplest way to store and house pallets when not in immediate use, roller racks are utilized in increasing storage capacity as they allow for the racks to move with ease along the pallet rack by the use of rollers. Read More…

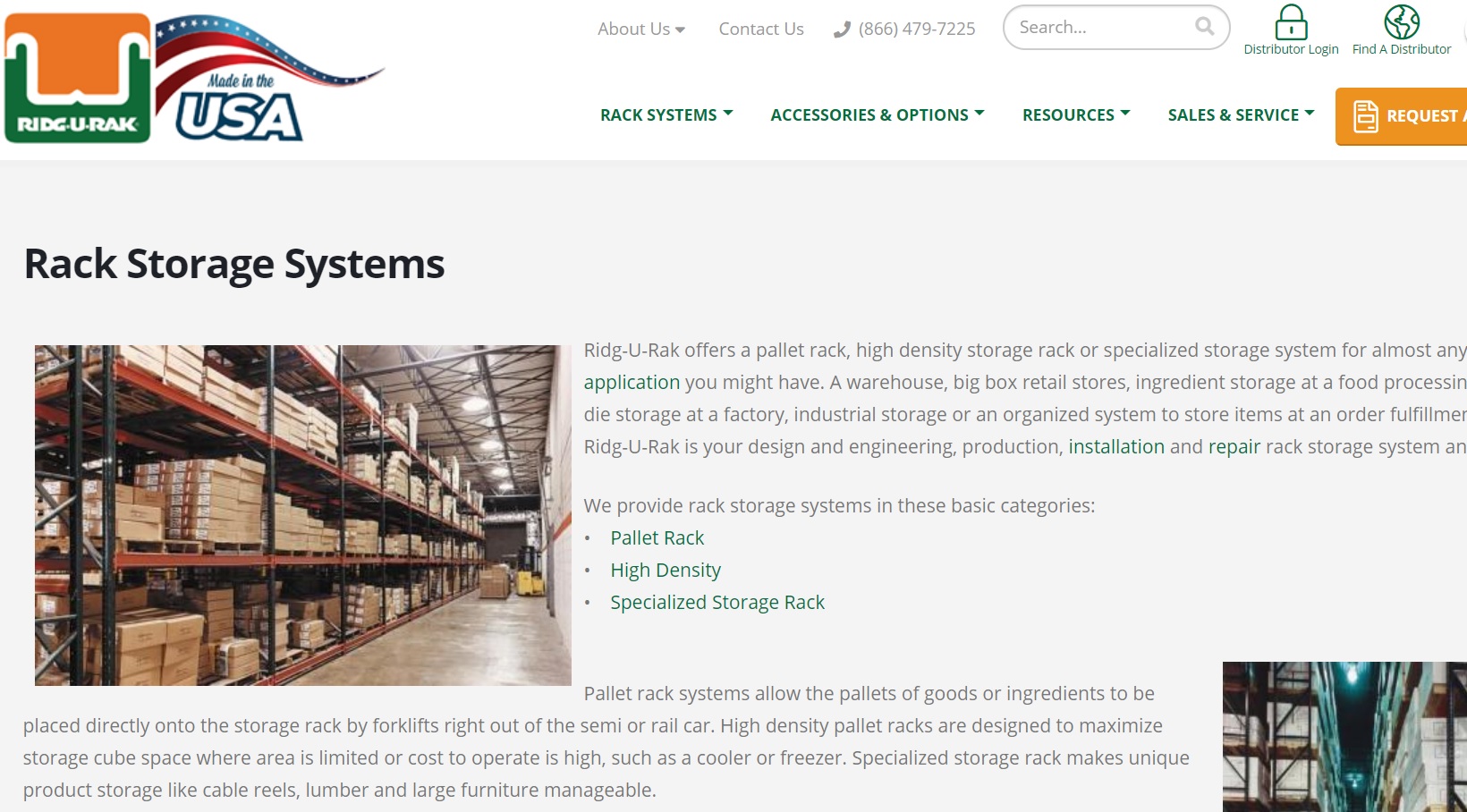

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

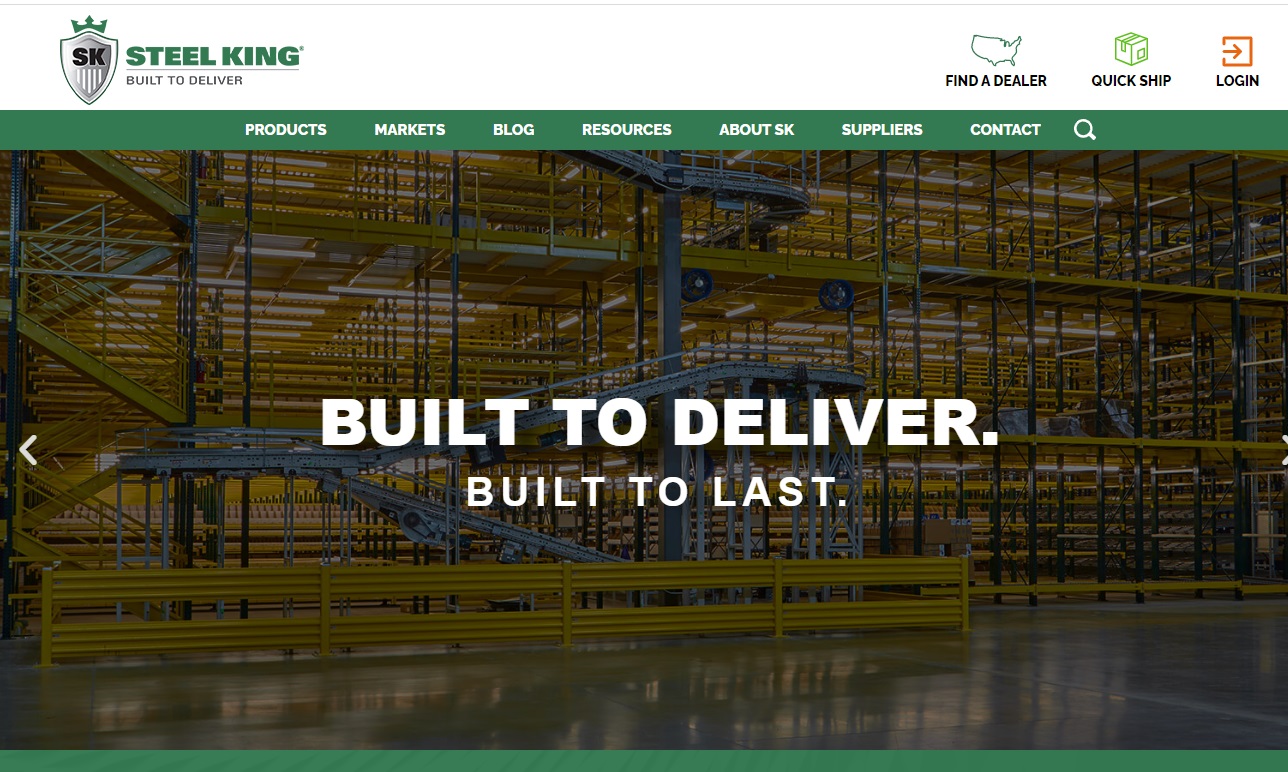

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

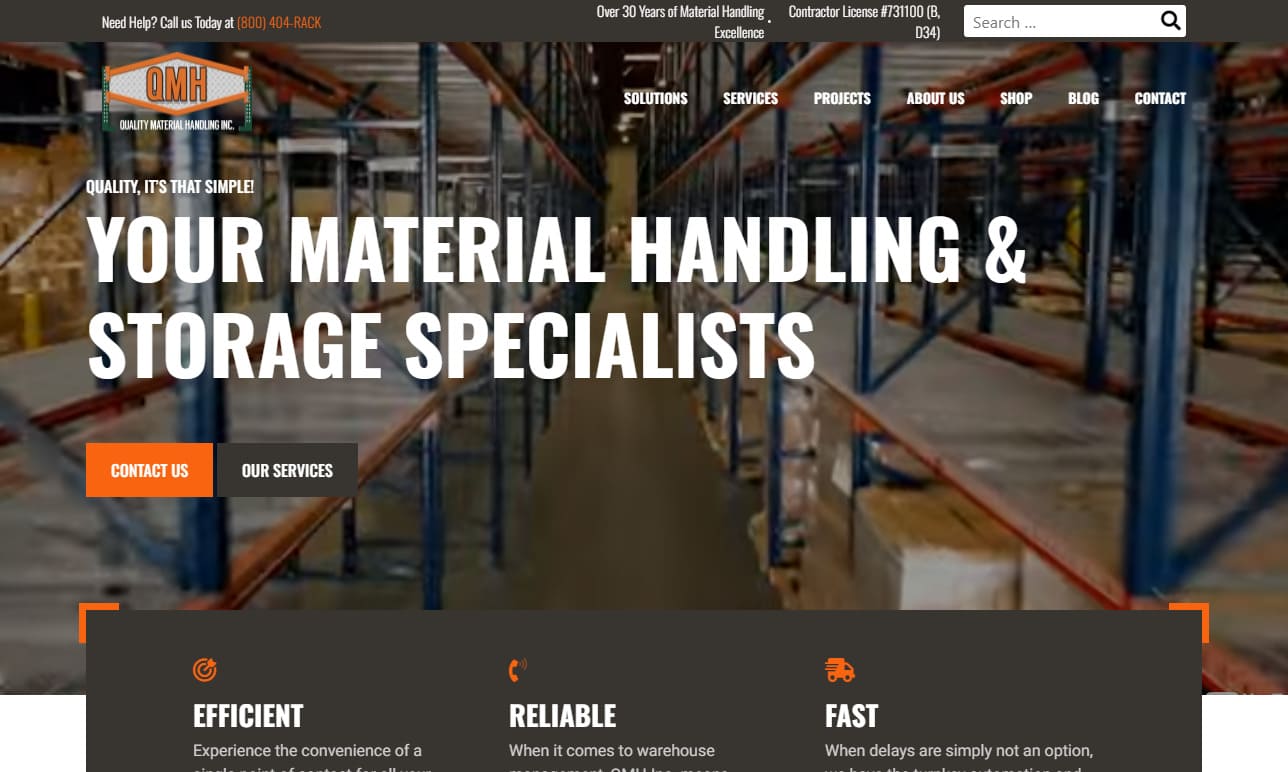

Quality Material Handling (QMH) is a leading total solutions provider for boltless shelving, warehouse racking, storage systems, mezzanines, and dock equipment. With over 29 years of experience and an in-house fabrication facility, QMH designs and manufactures innovative custom solutions such as dock platforms and ramps that solve difficult loading and unloading challenges. We are a full-service...

Established in 1972, RACK USA provides storage solutions for material handling applications. We design heavy load racks, medium load racks, retail fixtures, and custom industrial rack solutions. Hundreds of clients can attest to our expertise and dedication to quality.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

More Roller Rack Manufacturers

The rollers then allow racks to slide along with minimal force, whereas a typical rack solution requires the use of other equipment such as forklifts or anything similar. This rack style is highly appreciated when lots of movements happen constantly as the movement is allowed to be undertaken as effortlessly as possible but, at the same time, still provides a stable and safe storage area for racks.

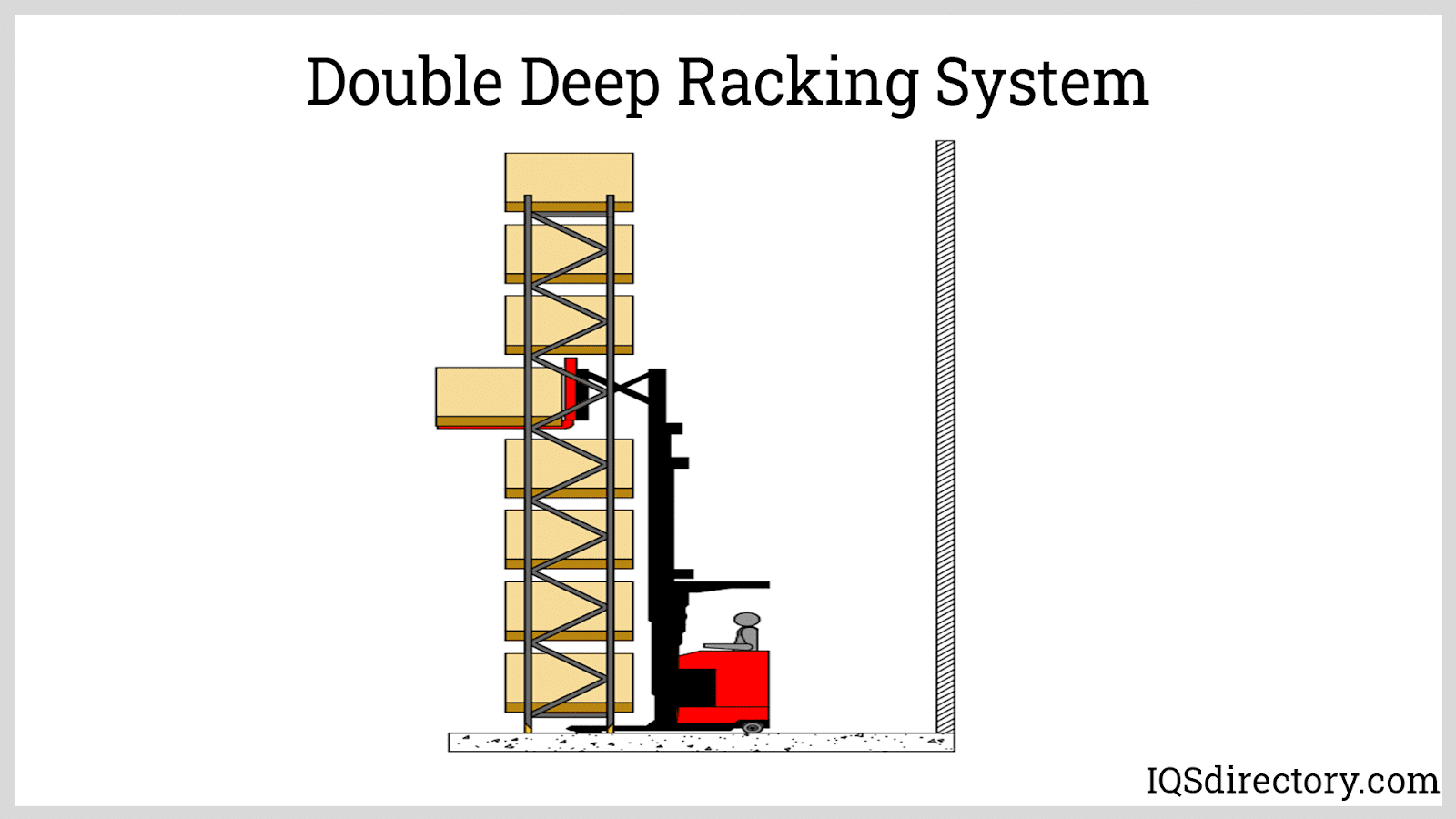

The high-density rack system is often portrayed with slanted rails of rollers to utilize gravity to a greater extent which assist in the movement of heavy pallets. Roller racks can be specified and grouped with rollers or wheels of various types and sizes. Roller tables have their racks supporting inclined wheels or rollers that allow racks to slide from the back to the front position.

How Roller Racks Function

Roller racks are a storage method that uses wheels (rollers) and gravity to accumulate and convey racks. When the first item, or the item placed in front is removed, the item next to it, or behind it, rolls onto the front position where the previous one was. This place or position may be considered to be the picking position. Speed controllers and brakes are used to control the descent and movement of items on the roller racks.

Roller Rack Installation

Roller racks can be installed to a height of 11 meters for first-in, first-out (FIFO) uses. With correct beam elevations, the first bay is erected. The first bay has to be plumb (perfectly vertical) in cross-aisle and down-aisle directions. Wedge locks from the inside through corner slots of connectors and columns must be properly installed. The remaining bays can now be installed by ensuring rows on the chalk line are straight and subsequent frames remain plumb in the cross-aisle and down-aisle directions.

Types of Roller Racks

The different types of roller racks include:

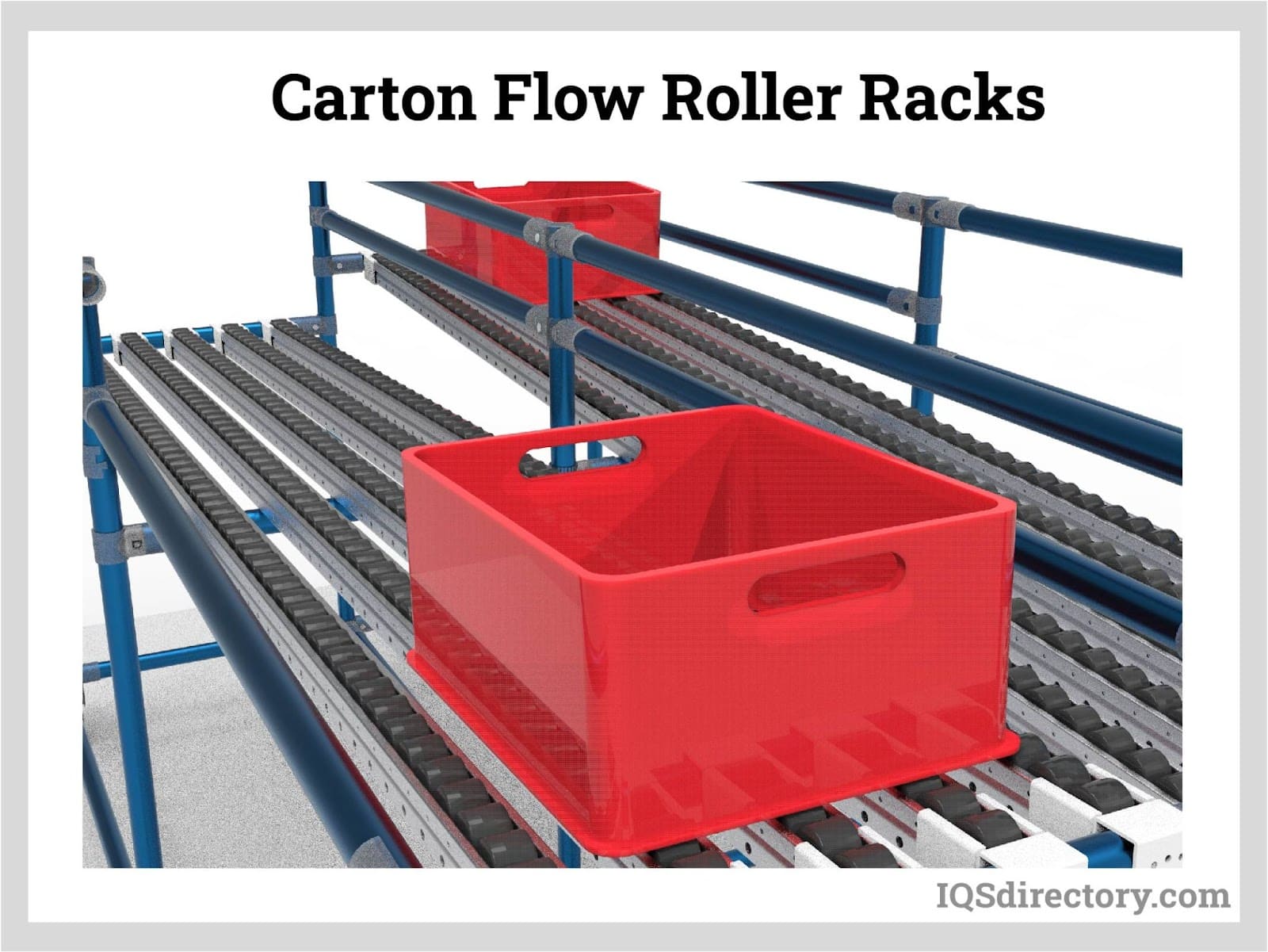

Carton Flow Roller Racks

Carton flow roller racks are a type of high-density storage that mainly focuses on the storage of cartons and similar light-weight products.

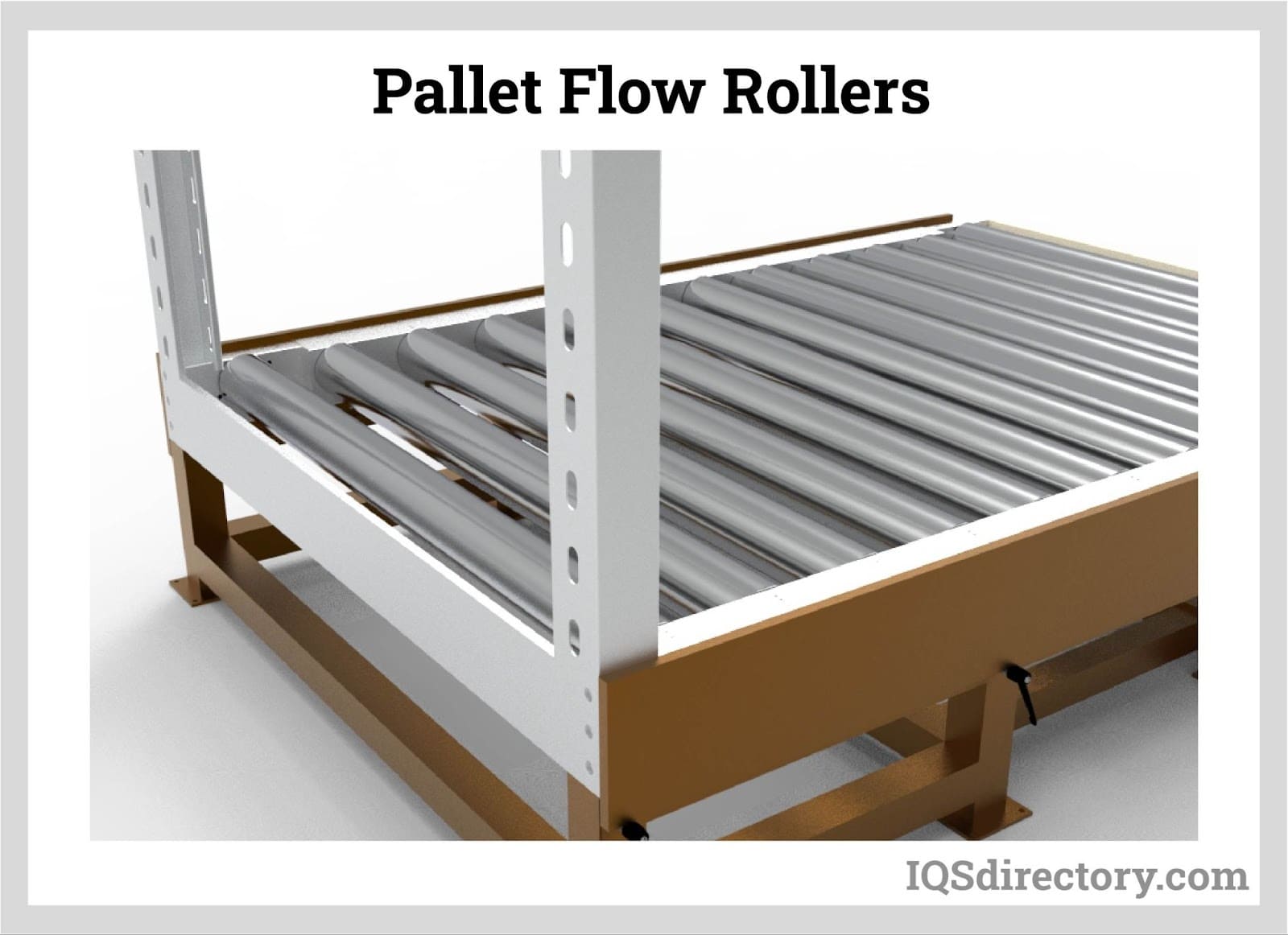

Pallet Flow Roller Racks

Pallet flow roller racks are also known as gravity flow racks. Pallet flow roller racks are similar to carton flow roller racks. Pallet flow roller racks store larger items on pallets instead of lightweight products. The addition of new pallets is done at the higher end while the removal of pallets is done at the lower end.

Pallet flow roller racks can double or triple capacity as compared to other pallet racking systems, making them suitable for food distribution centers, storage of perishable consumer goods, and freezer warehouses. Roll-Formed Cantilever Rack The cantilever roller rack has no upright aisles that obstruct horizontal space use so it is best suitable for storing bulky, longer items such as furniture, carpet rolls, tires, piping, textiles, and tubing. They have adjustable lock-joint pin locks that are safe, strong, and allow for easy height adjustment.

Applications of Roller Racks

- Roller racks are very adaptable and flexible. They can fit any system like conveyors or even carts.

- Roller racks can also help permanent structures like mezzanines because they do not allow fork truck traffic.

- Roller racks can be used to modify storage to existing pallet racks without replacing the entire racks.

Benefits of Roller Racks

- Roller racks allow extremely dense storage which, in turn, frees up additional space.

- Roller racks automatically replenish themselves by using a first-in, first-out tactic; employees at work on the front rack are not disadvantaged by disturbances of people loading more items at the back.

- Roller racks are time-saving storage solutions as they allow free movement of inventory.

- Roller racks are easy-to-use storage solutions as they require less labor to move inventory in the warehouse.

Choosing the Right Roller Rack Manufacturer

To make sure you have the most beneficial outcome when purchasing roller racks from a roller rack manufacturer, it is important to compare at least 5 manufacturers using our roller rack directory. Each roller rack manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each roller rack business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple roller rack businesses with the same form.

55 Gallon Drums

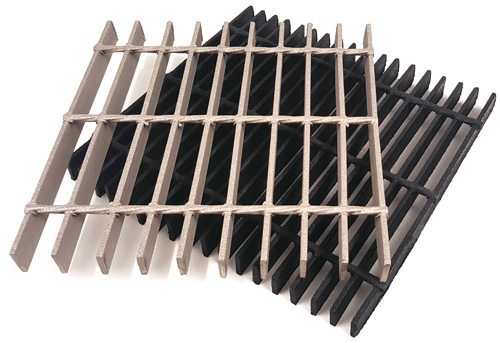

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services