Storage racks are a popular method of efficiently storing and organizing goods within an area in order to get the most effective use of available floor space as well as allowing for ease of accessibility to products and materials. Read More…

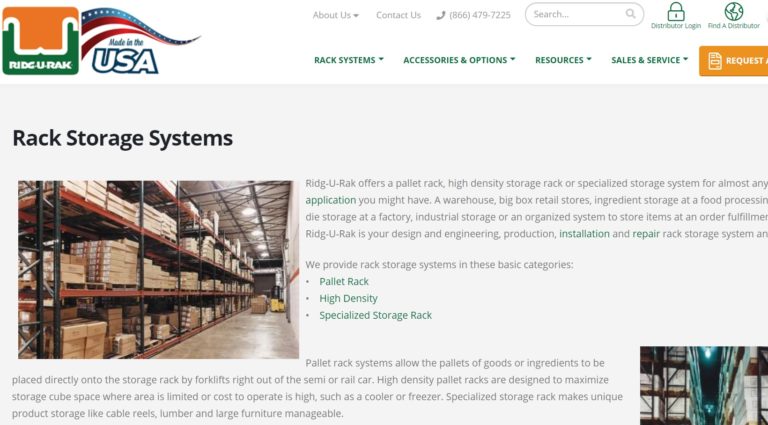

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

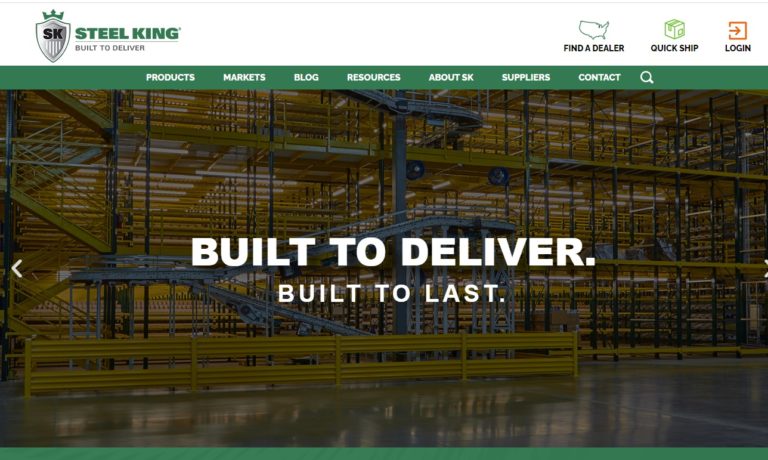

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

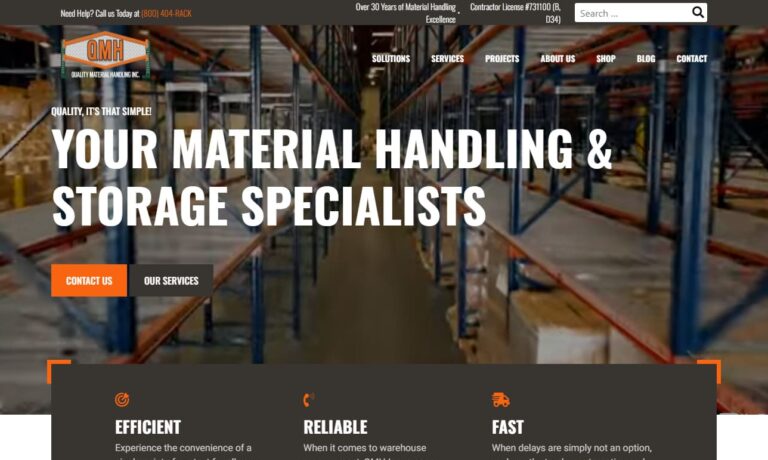

Quality Material Handling (QMH) is a leading total solutions provider for boltless shelving, warehouse racking, storage systems, mezzanines, and dock equipment. With over 29 years of experience and an in-house fabrication facility, QMH designs and manufactures innovative custom solutions such as dock platforms and ramps that solve difficult loading and unloading challenges. We are a full-service...

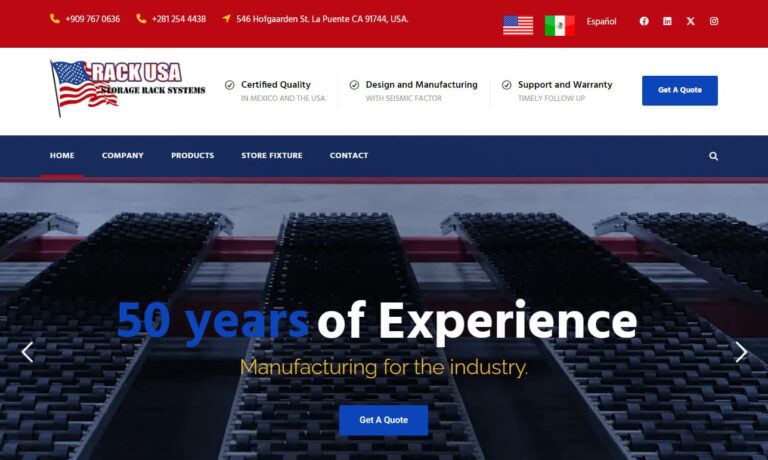

Established in 1972, RACK USA provides storage solutions for material handling applications. We design heavy load racks, medium load racks, retail fixtures, and custom industrial rack solutions. Hundreds of clients can attest to our expertise and dedication to quality.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

At North American Steel, our focus is on delivering top-tier storage solutions that optimize space and efficiency across industries. Specializing in the design, manufacturing, and installation of storage racks and steel shelves, we provide a comprehensive range of high-quality rack systems that cater to diverse storage needs.

Advance Storage Products produces structural and pushback rack systems. We emphasize unsurpassed quality, reliability and on-time delivery. Through outstanding execution, implementation and design we offer best in class industry solutions that make the most of our customers’ space. Our team approach insures your project receives the best engineering, project management and customer service to...

More Rack Manufacturers

Rack manufacturers can construct their racks to hold many different types of materials such as long carpet rolls, tubing, lumber, furniture, automotive bodies, palleted loads or boxed goods. They are available in many different dimensions and designs. Rack manufacturers design cantilever racks for the storage of long or oversized products such as piping or sheet metal.

The horizontal arms of a cantilever rack extend from a vertical support with any obstructing supporting at the end, allowing for ease of loading and unloading of unwieldy goods. Rolling racks use the addition of rollers in the horizontal arm components of a racking system to help with moving heavy loads. Other types of racks might be slightly inclined or use push back or pull-forward methods to improve the efficiency with which products are moved and stored.

Some specialized warehouse racking systems can have added features such as automated conveyor or lifting systems, rack accessories such as wheels or guard rails and other customizations such as wire mesh or coatings and finishings. Many racks can also be adjusted in terms of components in order to fit specific products or areas. Extension arms, vertical beams and braces can often be added to increase the structural load capability.

Rack manufacturers have to take into account both the materials with which the racks will be used as well as the location and intended length of use for the racking system. Typically metals such as steel and aluminum are used to construct industrial storage racks as they are strong and durable. The frames and bearing arms of storage racks are typically bolted or welded together for the most secure load-bearing capability.

For many applications, the storage rack will have to endure a heavy load and therefore needs to be able to withstand that load for extended periods of time. Careful design and assembly of storage systems is important to ensure the safety of personnel within the storage area as well as the protection of goods from possible structure failure. Overloading or misuse of the storage rack could have disastrous results and rack manufacturers need to take every precaution to avoid this.

55 Gallon Drums

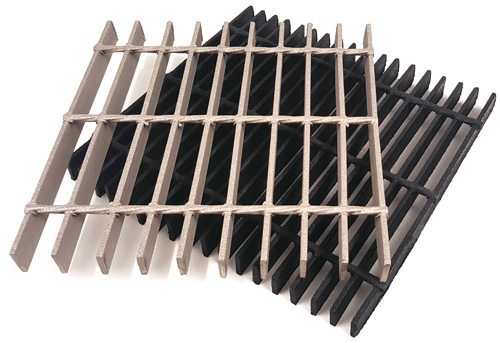

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services